Faced with the increasing demand for personalized customer requirements, CNC acrylic services stand out due to their high precision and flexibility. They can accurately realize customers’ design concepts and create unique products. This article will analyze the core advantages of CNC acrylic services in meeting customer personalization from a professional perspective.

The importance of CNC acrylic services in responding to personalized needs, How exactly does CNC technology transform customer’s ideas into tangible products and demonstrate its advantages in the customization process? We will delve into the specific embodiments of CNC acrylic services in terms of design freedom, precision control, rapid iteration, and material diversity.

How does CNC enhance design freedom for acrylic?

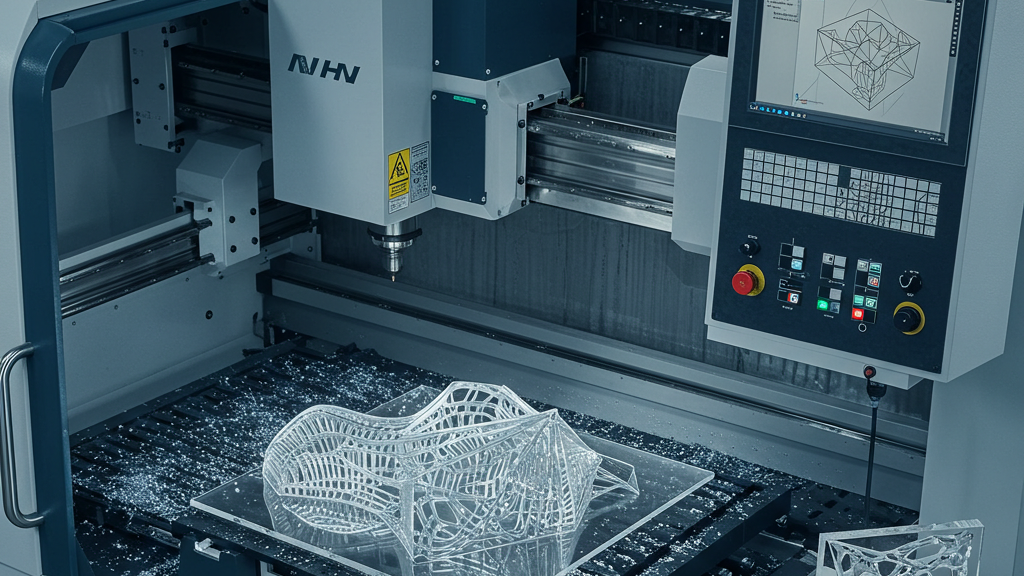

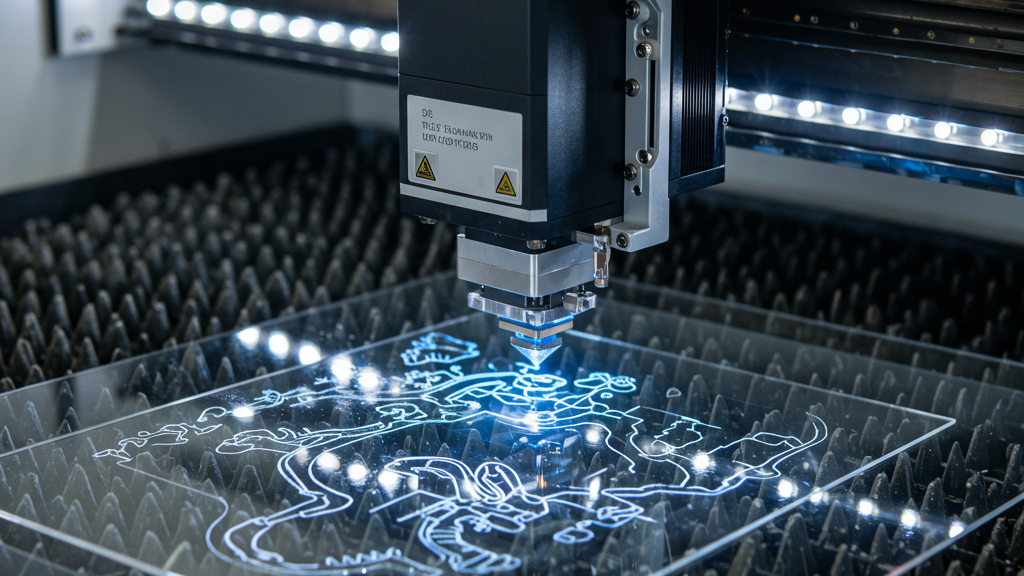

The exquisite craftsmanship of CNC technology brings unprecedented liberation to the design of acrylic materials. Whether it’s complex geometric shapes or fine pattern engraving, CNC can accurately realize them, greatly expanding the designer’s creative space.

- Complex Geometry: CNC technology can precisely cut complex three-dimensional geometric shapes, unleashing the infinite possibilities of design styling.

- Fine Engraving: CNC can flexibly engrave fine patterns and text on the acrylic surface, achieving highly personalized visual expression.

- Multi-Layer Hollow-Out: CNC easily constructs multi-layered and hollow-out effects, creating a sense of three-dimensionality and unique structural design.

- Parametric Design: Combined with software, CNC supports parametric design to quickly generate multiple variants, enhancing customization flexibility.

How does CNC ensure precision in acrylic personalization?

The application of CNC (Computer Numerical Control) technology fundamentally ensures the accuracy of acrylic personalization. Through rigorous digital models and automated control, CNC machining can achieve micron-level precision, perfectly presenting the customer’s design details.

- Digital Model: CNC relies on precise digital model instructions to eliminate human error at the source and ensure machining accuracy.

- Servo Sensing: High-precision servo systems and sensors achieve micron-level motion control, ensuring the accuracy of dimensions and shapes.

- Automated Process: CNC automated machining processes reduce human intervention, ensuring product quality stability and consistent accuracy.

- Precision Tooling: Precision tools and fixture systems ensure material stability and cutting accuracy during the machining process, enabling high-precision manufacturing.

What efficiency advantages does CNC offer in acrylic customization iteration?

In today’s fast-paced consumption and growing demand for personalization, product iteration speed is a key to business competition. CNC technology applied to acrylic customization significantly shortens the iteration cycle with its unique efficiency advantages, helping businesses respond quickly to market changes.

- Rapid Modification: CNC efficiently responds to design changes by quickly reading new digital models, shortening the iteration cycle.

- Small Batch Flexibility: CNC can quickly switch programs to adapt to small-batch, high-variety customization, enabling efficient flexible production.

- Rapid Prototyping: CNC rapidly creates prototypes for customer evaluation and testing, accelerating product development and design optimization iteration.

- Parameter Convenience: Parametric design combined with CNC systems allows for quick customization by conveniently adjusting parameters, improving iteration efficiency.

Selection of diversified materials for CNC acrylic

|

Material Property |

CNC Machining Advantage |

Personalized Application Examples |

| Color Selection | Wide range of transparent, translucent, and opaque colors available. | Colorful Logos, Themed Decorations, Brand-Colored Product Components |

| Thickness Selection | Supports processing various thicknesses for different needs. | Thin Signage, Thick Bases, Components with Different Load Bearings |

| Special Effects | Can process frosted, mirrored, UV-printed, light-guiding, etc. | Frosted Artwork, Mirror Decorations, Backlit Signs, Light Guides |

| Composite Materials | Can handle acrylic combined with metals, wood, etc. | Metal-Based Acrylic Displays, Wood-Veneered Signs, Multi-Material Art |

Four Key Advantages of CNC Acrylic Personalization

CNC acrylic services demonstrate significant advantages in design freedom, precision assurance, customization iteration efficiency, and material diversity. These advantages interact to not only give designers and customers greater creative space, ensure high product quality and uniqueness, but also greatly improve the efficiency and flexibility of the customization process.

1.Design Freedom: CNC technology empowers acrylic customization with unlimited design possibilities, easily realizing complex creative ideas.

2.Precision Quality: CNC machining ensures excellent precision and quality in acrylic customization through high-precision control.

3.Efficient Iteration: CNC helps acrylic customization achieve rapid design adjustments and flexible small-batch production.

4.Material Diversity: CNC acrylic services offer a wide range of material and effect choices to meet personalized needs.

Conclusion

In summary, CNC acrylic services demonstrate strong advantages in meeting the increasing personalization needs of customers through their unlimited expansion in design freedom, strict assurance of product precision and quality, efficient and flexible customization and iteration capabilities, and broad support for diverse materials and effects.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Apr-18-2025